Hot processed O/W emulsion with Ceramides

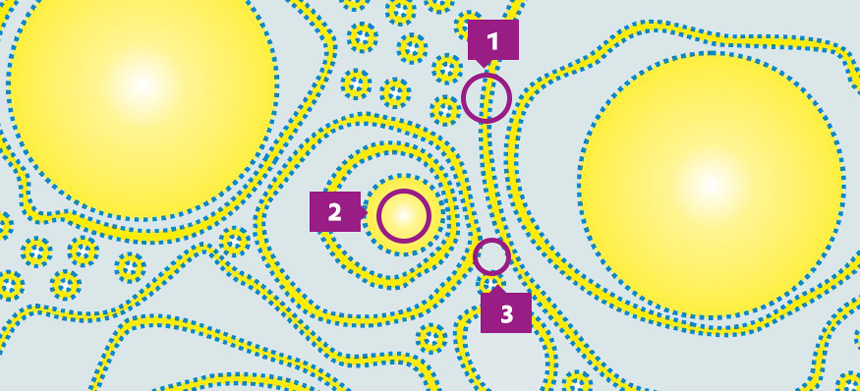

Stabilization of Ceramides by the lamellar structure of O/W emulsions

- Mixed crystalls of hydrophilic emulsifier and polar waxes

- Dispersed oil

- Aqueous phase

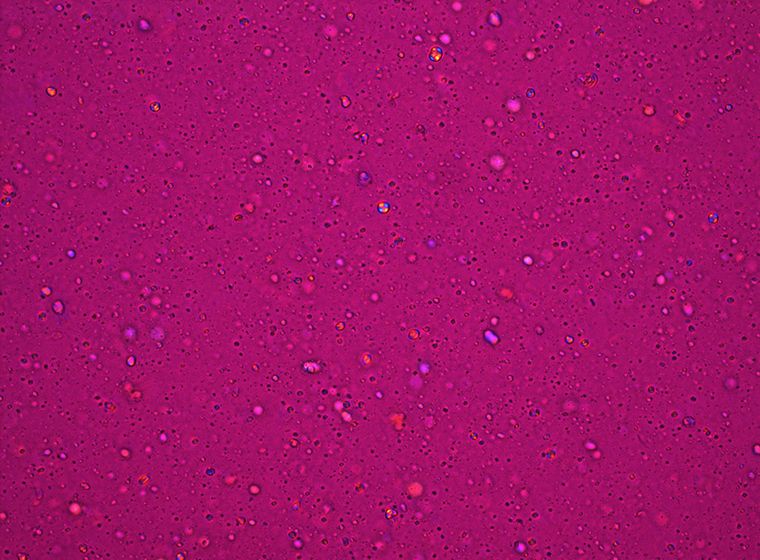

Three-dimensional network of liquid-crystalline (lamellar) structures consisting of emulsifier and consistency agents such as Glyceryl Stearate and Stearyl Alcohol.

Hot processed O/W emulsion with Ceramides

Stabilization of Ceramides by lamellar stuctures in O/W emulsions

| Phase | Ingredients | w/w% | w/w% |

|---|---|---|---|

| A | TEGO® Care 450 (Polyglyceryl-3 Methylglucose Distearate) | 3.0 | |

| TEGINACID C (Ceteareth-25) | 2.0 | ||

| TEGIN® M Pellets MB (Glyceryl Stearate) | 2.0 | 4.5 | |

| Stearyl Alcohol | 1.0 | 1.5 | |

| Ceramide III (Ceramide NP) | 0.2 | 0.2 | |

| B | Water | 93.8 | 91.8 |

| Preservative | q.s. | q.s. |

Test formulations consist of emulsifier, consistency agents, Ceramide III and water. No emollients are present.

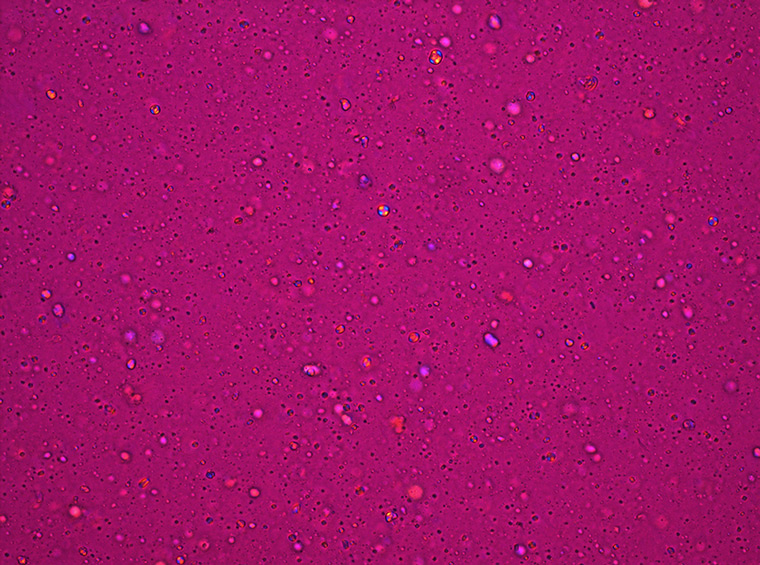

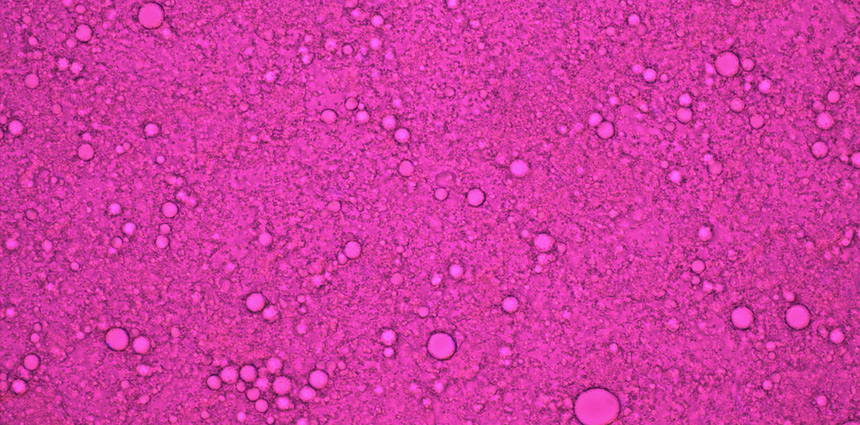

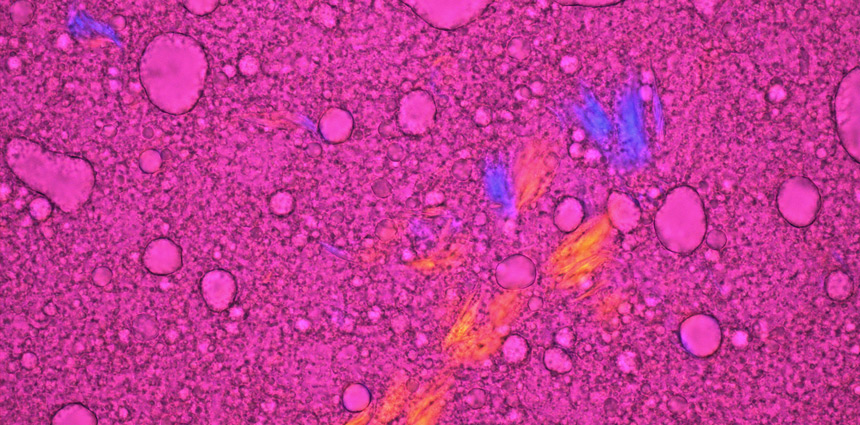

- No crystalls are visible because Ceramide III is incorporated in the lamellar structure of the emulsion.

- No recrystallization of the Ceramides during storage.

- The stabilization of Ceramides by the lamellar sturcture is independant of the emollients in the formulation.

As long as the O/W emulsion contains lamellar structures the type of emollients used in the cosmetic formulation is almost not limited.

TEGO® Care 450

TEGINACID® C

Hot processed O/W emulsion with Ceramides

Influence of the Ceramide concentration on the properties of O/W Creams

| Phase | Ingredients MAC 853 |

w/w% 1 |

w/w% 2 |

w/w% 3 |

w/w% 4 |

|---|---|---|---|---|---|

| A | ABIL® Care XL 80 MB (Bis-PEG/PPG-20/5 PEG/PPG-20/5 Dimethicone; Methoxy PEG/PPG 25/4 Diemthicone; Caprylic/Capric Triglyceride) | 2.00 | 2.00 | 2.00 | 2.00 |

| TEGINACID® C (Ceteareth-25) | 0.50 | 0.50 | 0.50 | 0.50 | |

| TEGIN® M Pellets MB (Glyceryl Stearate) | 1.50 | 1.50 | 1.50 | 1.50 | |

| Stearyl Alcohol | 2.00 | 1.90 | 1.80 | 1.50 | |

| TEGOSOFT® OS (Ethylhexyl Stearate) | 8.50 | 8.50 | 8.50 | 8.50 | |

| Ceramide III (Ceramide NP) | 0.10 | 0.20 | 0.50 | ||

| B | Glycerin | 3.00 | 3.00 | 3.00 | 3.00 |

| Water | 71.00 | 71.00 | 71.00 | 71.00 | |

| C | Carbomer | 0.20 | 0.20 | 0.20 | 0.20 |

| TEGOSOFT® OS (Ethylhexyl Stearate) | 0.80 | 0.80 | 0.80 | 0.80 | |

| D | Sodium Hydroxide (10% in water) | 0.70 | 0.70 | 0.70 | 0.70 |

| Z | Euxyl PE 9010 | 0.70 | 0.70 | 0.70 | 0.70 |

Processing

- Heat phase A and B separately to approx. 90 °C.

- Add phase A to B with stirring.1)

- Homogenize.

- Cool with gentle stirring to approx 60°C and add phase C.

- Homogenize for a short time.

- Add phase D below 40 °C with stirring.

1) Important: If phase A has to be charged into the vessel first, phase B must be added without stirring

Hot processed O/W emulsion with Ceramides

Influence of the Ceramide Concentration on the Properties of O/W Creams

| Without Ceramide III | 0.1% Ceramide III | 0.2% Ceramide III | 0.5% Ceramide III | |

|---|---|---|---|---|

| Appearance at 90 °C | blue shine | blue shine | blue shine | blue shine |

| Appearance at 20 °C | brilliant | brilliant | brilliant | brilliant |

| after 5 freeze/thaw cycles (-15 °C/20 °C) |

Homogeneous | Homogeneous | Homogeneous | Homogeneous |

| Mean droplet size | Increasing droplet size → | Increasing droplet size → | Increasing droplet size → | Increasing droplet size → |

| Viscosity of the emulsion [Pas] | 130 | 147 | 150 | 192 |

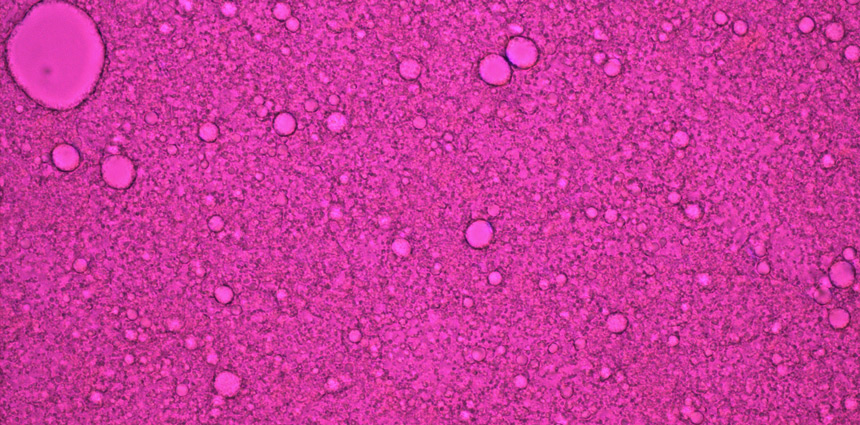

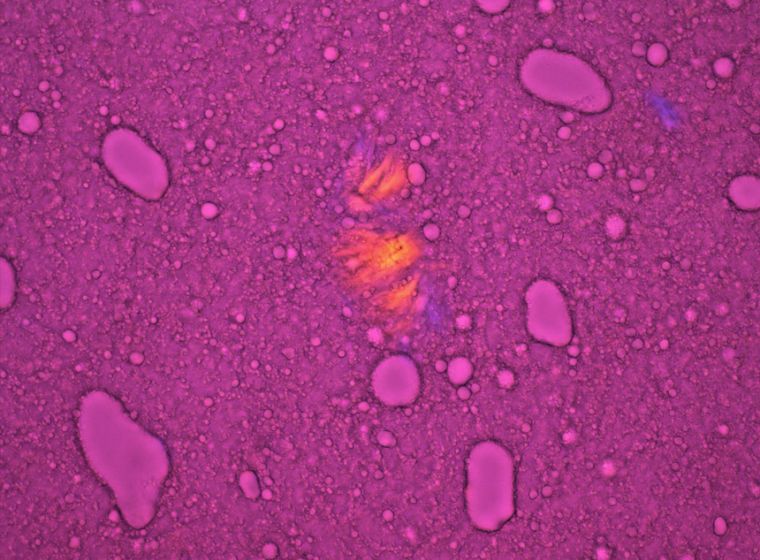

| 3 Mo Room temperature | No recrystallization | No recrystallization | No recrystallization | Ceramide crystalls |

With Ceramide concentrations of 0.2% or lower a recrystallization of the Ceramide III was not observed.

Without Ceramide III

0.2% Ceramide III

0.5% Ceramide III

Hot processed O/W emulsion with Ceramides

General formulation hints

- Ceramides are stabilized by the lamellar structure of O/W emulsions.

- < =0.2% Ceramides: As long as the O/W emulsion contains lamellar structures the composition and the concentration of the oil phase is not limited.

- >=0.2% Ceramides: if higher concentration of Ceramides should be applied a recrystallization of the Ceramides might occur. It can be avoided by emollients with higher polarity and by higher oil phase contents.

- Emollients with a high polarity help to decrease the solubilization temperature of Ceramides in the oil phase of the emulsion.

- Ceramide IIIB requires a lower solubilization temperature compared to Ceramide III or VI.

Hot processed O/W emulsion with Ceramides

Caring & Soothing Body Lotion (MAC 804/1/2)

| Phase | Ingredients | w/w% |

|---|---|---|

| A | TEGO® Care LTP MB (Sorbitan Laurate; Polyglyceryl-4 Laurate; Dilauryl Citrate) | 2.0 |

| TEGIN® Pellets MB(Glyceryl Stearate SE) | 3.0 | |

| TEGO® Alkanol 1618 (Cetearyl Alcohol) | 0.5 | |

| TEGOSOFT® MM MB (Myristyl Myristate) | 1.0 | |

| TEGOSOFT® P (Isopropyl Palmitate) | 4.0 | |

| ABIL® 350 (Dimethicone) | 2.0 | |

| Myristyl Alcohol | 0.5 | |

| Isohexadecane | 5.0 | |

| Paracera W 80 (Cera Microcristallina) | 0.5 | |

| CERAMIDE IIIB (Ceramide NP) | 0.1 | |

| B | Glycerin | 5.0 |

| Panthenol | 0.5 | |

| Water | 70.9 | |

| C | TEGO® Carbomer 141 (Carbomer) | 0.2 |

| Mineral Oil | 0.8 | |

| D | TEGO® Natural Betaine (Betaine) | 2.0 |

| Water | 2.0 | |

| E | Sodium Hydroxide (10 % in water) | q.s. |

| Z | Preservative, Perfume | q.s. |

Processing

- Heat phase A and B separately to approx. 80 °C.

- Add phase A to B with stirring.1)

- Homogenize.

- Cool with gentle stirring to approx 60°C and add phase C.

- Homogenize for a short time.

- Add phase D and E below 40 °C with stirring.

1) Important: If phase A has to be charged into the vessel first, phase B must be added without stirring

80 °C are sufficient for the solubilization of Ceramide IIIB.

Hot processed O/W emulsion with Ceramides

O/W Anti-Age Face Cream (F 48/08-4)

| Phase | Ingredients | w/w% |

|---|---|---|

| A | TEGO® Care 450 (Polyglyceryl-3 Methylglucose Distearate) | 3.0 |

| TEGIN® M Pellets MB (Glyceryl Stearate) | 2.0 | |

| Stearyl Alcohol | 2.0 | |

| TEGOSOFT® MM MB (Myristyl Myristate) | 2.0 | |

| TEGOSOFT® CT (Caprylic/Capric Triglyceride) | 9.0 | |

| TEGOSOFT® P (Isopropyl Palmitate) | 4.0 | |

| Simmondsia Chinensis (Jojobe) Seed Oil | 3.0 | |

| CERAMIDE IIIB (Ceramide NP) | 0.1 | |

| B | Water | 71.90 |

| Glycerin | 3.0 | |

| Z | Preservative, Perfume | q.s. |

Processing

- Heat phase A and B separately to approx. 75 °C.

- Add phase A to B with stirring.1)

- Homogenize.

- Cool with gentle stirring

1) Important: If phase A has to be charged into the vessel first, phase B must be added without stirring

With suitable oilphase Ceramide IIIB can be processed at 75 °C.

Hot processed O/W emulsion with Ceramides

Face & Body Cream (F 11/10-5)

| Phase | Ingredients | w/w% |

|---|---|---|

| A | TEGO® Care PSC 3 MB (Polyglyceryl-3 Citrate/Stearate) | 3.0 |

| TEGIN® M Pellets MB (Glyceryl Stearate) | 1.2 | |

| Stearyl Alcohol | 1.3 | |

| TEGOSOFT® OER MB (Oleyl Erucate) | 5.0 | |

| TEGOSOFT® CT (Caprylic/Capric Triglyceride) | 8.5 | |

| Persea Gratissima (Avocado) Oil | 6.0 | |

| CERAMIDE III (Ceramide NP) | 0.1 | |

| B | Water | 66.9 |

| Glycerin | 3.0 | |

| C | Water | 3.8 |

| Keltrol CG-SFT (Xanthan Gum) | 0.2 | |

| D | Sodium Hydroxide (10% in water) | 0.2 |

| E | Rokonsal BSB-N (Benzyl Alcohol; Benzoic Acid; Sorbid Acid) | 0.8 |

| Z | Perfume | q.s. |

Processing

- Heat phase A and B separately to approx. 90 °C.

- Add phase A to B with stirring.1)

- Homogenize.

- Cool with gentle stirring and add phase C below 40 °C.

- Add phase D.

- Add phase E and adjust the pH to 5.0-5.5.

1) Important: If phase A has to be charged into the vessel first, phase B must be added without stirring

Ceramide III has to be solubilized at 90 °C in the hot oil phase.

Hot processed O/W emulsion with Ceramides

Summary

- The Ceramides have to be solubilized in the hot oil phase.

- No limitation regarding the composition of the oil phase as long as the formulation contains lamellar phases and as long as the Ceramide concentration does not exceed 0.2%.

- Higher concentration of Ceramides might recrystallize. Then the use of an higher amount of polar emollients and/or a higher oil phase content are recommended.

- The more polar the oil phase is the lower the solubilization temperature of the Ceramides will be.

- Comparing the Ceramides of our portfolio Ceramide IIIB needs the lowest solubilization temperature.